300 mm Wafer Service

Blank Wafer

300 mm Blank Wafer

Silicon based Layer

- SiO2 (thermal or chemical formed oxide)

- Organo silicate glass (SiCOH/ULK) [porous]

- SiGe

- Doped amorphous Si and poly Si (P, B)

Metals

- PVD: Ta(N), Ti(N), Cu

- CVD: Co

- ECD: Co, Cu

ALD based Oxides and Nitrides

- Al2O3

- HfO2 (doped)

- ZrO2

- More materials upon request

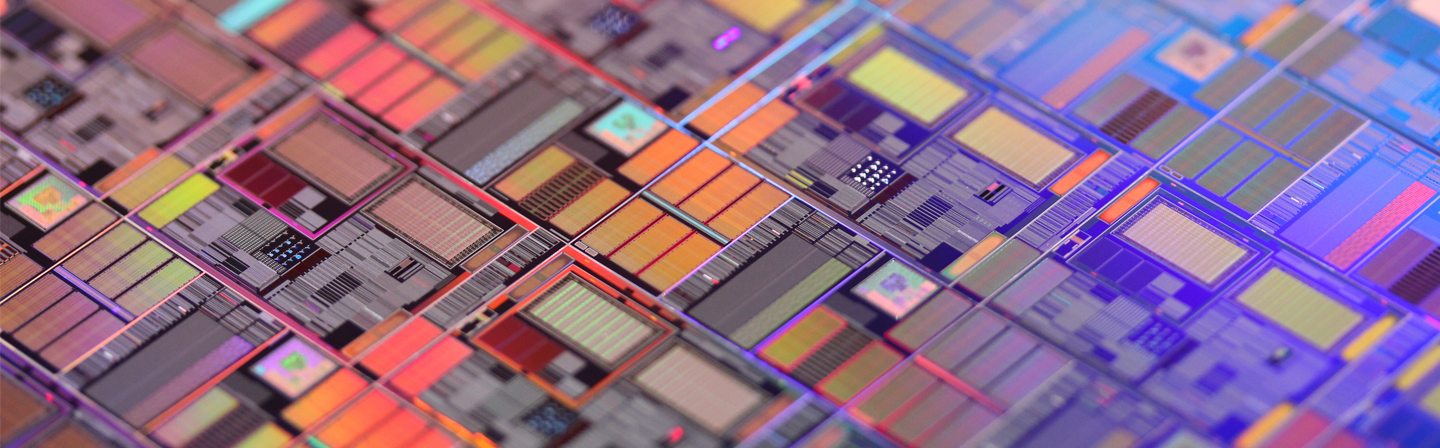

Structured Wafer for CMOS (FEoL/BEoL)

300 mm Structured Wafer

Test Structures for various Processes at ≤ 28 nm Technology Node

- CMP | Plating | Cleaning

- Thin films | STI

Test Structures for functional Layers

- Memory applications

- MIS/MIM structures

Custom Layout Implementation / E-Beam Lithography Nanopatterning

- Complementary Mix & Match

- Small volume series

- more information here!

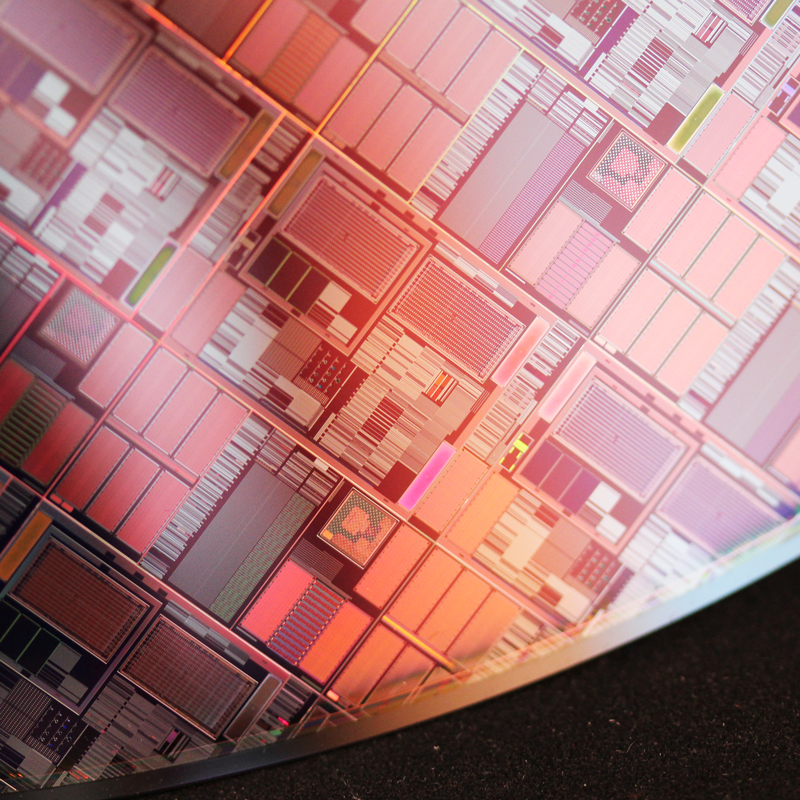

Test Structures for BEOL / Wafel Level Packaging (IZM-ASSID)

- TSV Test Wafers (via middle, via last)

- Si Interposer with Cu-TSV

- Fine pitch flip Interconnects

- Teships for chip-to-wafer / chip-to-chip / chip-to-substrate bonding

Structured Wafer for Wafel Level Packaging

- TSV Test Wafers (via middle, via last)

- Si Interposer with Cu-TSV

- Fine pitch flip Interconnects

- Testchips for chip-to-wafer / chip-to-chip / chip-to-substrate bonding

Wafer Thinning

- Grinding and polishing of single and compound wafers

- Stress relief etching, Chip-Side-Wall-Healing

- TAIKO wafer processing

Separating

- Mechanical Blade-Dicing, Laser-Grooving

- Laser Stealth-Dicing, Wafer-Edge-Trimming; Circle-Cut

Assembly

- Die to Wafer /Interposer Assembly (Flip Chip soldering)

- Wafer to Wafer temporary and permanent bonding

- Thermo-compression, anodic Wafer Bonding, Hybrid Bonding

High-density and ultra fine Pitch Interconnect Formation

- Galvanic deposition technology

- Solder bumping: SnAg, In, InSn, AuSn, Sn

- Pillar bumping: Cu, Au, Ni, porous nano-gold

- Single-Chip-Bumping on Carrier wafers

- Ultra-Fine-Pitch Bumping < 10µm

TSV Integration

- Front- / Backside TSV

- Cu-TSV liner, full-filled, FS Via-middle, BS Via –Last, Via -First

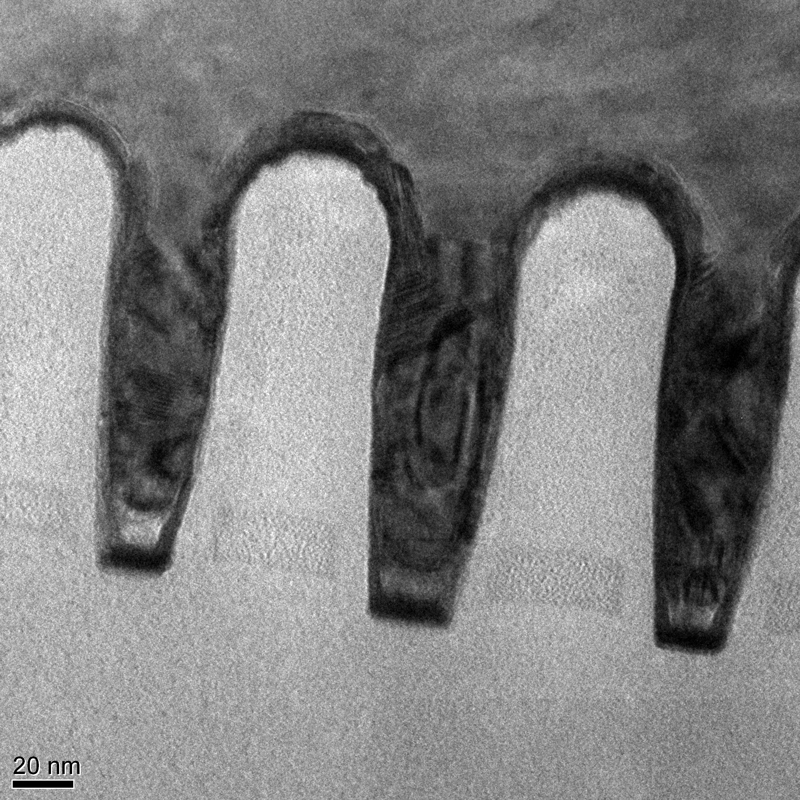

Metrology

Test wafers are verified in our metrology system park for a fast realization of further qualification steps on site.

Picture of an EFTEM (Energy filtered transmission electron microscopy)

- Layer thickness and uniformity

- (4-point probing, ellipsometry, XRR, high res. profi lometry)

- Film morphology and structure

- (AFM [3D], XRD, surface inspection, SEM, TEM, porosimetry)

- Chemical composition & contamination

- (ToF-SIMS, XPS, TXRF, REELS, ICP-MS, AAS)

- Patterned defect inspection

- Electrochemical monitoring of electrolyte solutions and additives

- (CVS, LP, EIS, etc.)

- Electrical characterization of functional layers and layer stacks

- (Semi-automatic probing)

Material

Involved Partners

in cooperation with: