For a self-organizing, user-oriented and demand-driven automated production (Industry 4.0), smart functionalities have to be integrated into mechanical engineering systems. To implement such functionalities, a large variety of connected, structure-integrates sensors and actuators will be required. These devices have to be robust combined with a small form factor and should be able to communicate via wireless data links.

A promising approach towards that goal is the functional and structural integration of microelectronic and micromechanical devices and subsystems into machine tools and components of manufacturing systems.

It is often challenging to achieve a process-controlled condition monitoring at hardly accessible positions inside the machines and constructions. Therefore, miniaturized, networked and energy-efficient information and communication technologies (ICT) have to be integrated into machine tool parts.

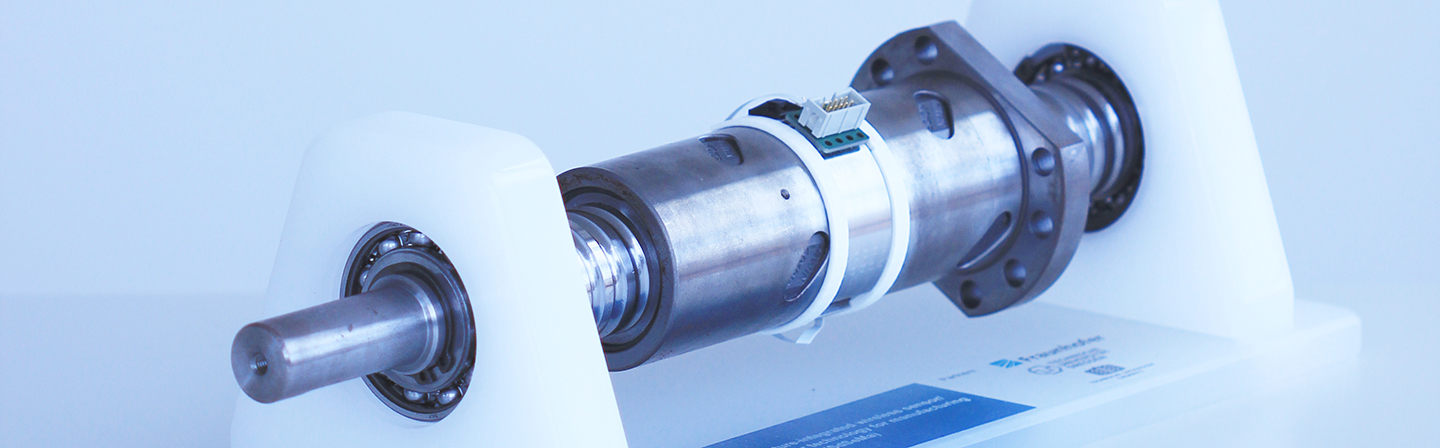

A joint research team from the High Performance Center »Functional Integration in Micro- and Nanoelectronics« and Fraunhofer IWU works together on the conception, engineering and test of structure-integrated sensor and actuator systems in machine parts. Here, exemplarily shown for a ball screw drive, a structure-integrated wireless sensor technology is implemented into a manufacturing system for advanced process control and status monitoring.

PROJECT DETAILS:

Concept:

- Providing a technology development platform to enable smart “Industry 4.0” functionalities in mechanical engineering systems implementing sensors and actuators

- Functional integration of microelectronic and micromechanical devices and subsystems into components of manufacturing systems

- Exemplary use case: “intelligent” ball screw drive with built-in sensor ring

R&D objectives:

- Full structural integration of all key electronic components through rigorous miniaturization

- Wireless data transmission out of a metal shielded environment

- Power supply and management for wireless IoT solutions

- Improved functionality, robustness and reliability

Added value:

- Increase in overall equipment effectiveness (OEE)

- Condition-dependent scheduling of maintenance intervals

- Better monitoring of production processes

Targeted applications:

- Condition monitoring

- Predictive maintenance

- Adaptive process control